Assembly and Manufacture of Machinery

Complete Solutions - One Address

Home > Assembly

The heart of our activity is machine assembling, based on manufacturing engineering solutions. We provide a complete service package that allows our customers to present a build to print, at the end of the process. A machine is manufactured at the highest quality and completely reliable, all in accordance with our customer’s needs.

We are certified to work by international aviation and medical quality standards as well as by military standards; we are thus approved for the manufacture of machinery, sub-assemblies, and cabling for these industries. The company’s engineering department employs experienced professionals in the fields of electricity, electronics, and machinery. The engineering department provides full engineering assistance from your initial design phase to the completion of the machine’s construction.

Our customers enjoy a full-service package that includes quality raw materials, accurate and uncompromising workmanship, and strict adherence to schedules and delivery times.

Why Us?

One Address and One Point of Responsibility for the entire Manufacturing Process

Professional and Experienced Staff to guide you through the Engagement

Immediate Availability of Exceptional Raw Materials for Fast Delivery of final Poducts

Certification for Medical and Military Sectors

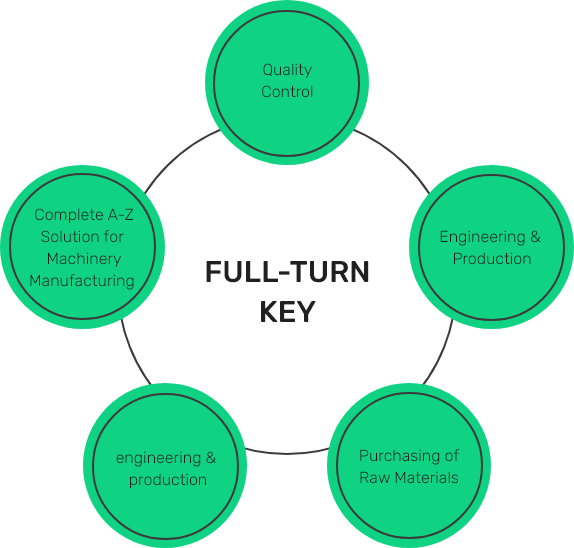

The Process

Our customers enjoy one address throughout the manufacturing process: a single point of contact with the skill and experience to address every matter that arises.

The process begins with examining the feasibility of production. After approval to start, we return and perform a thorough engineering inspection; we raise issues that should be discussed before production begins, in coordination with the customer.

Next, we build a prototype and manufacture the actual product after its approval.

Throughout the process, there is ongoing communication between our team and the customers, in which we recommend worthwhile improvements and highlight issues that arise along the way, in order to ensure efficient, fast, and high-quality production.

At the end of the process, we perform various tests to ensure quality: HIGH POT, QA, QC, ATP, TESTING, and various integration tests as relevant.